History

Over the past 32 years, a quiet little company has grown from a part-time hobby to a full-time enterprise that blends the best of old world craftsmanship and new world technology.

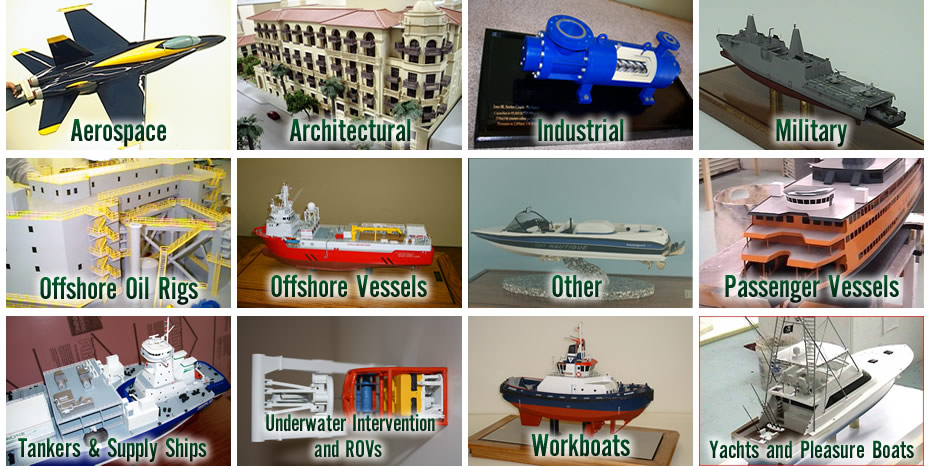

They've grown by staying small. Literally. The company, Scale Reproductions, builds models, but not the kind you buy at the hobby store. They specialize in detailed custom reproductions for corporate offices, concept presentations, museums and trade shows worldwide.

The company that was founded in the mid-70's now has a crew of 12 full-time employees and a 7000 square foot facility located in Foley, Alabama. The company's output of three to four models a year in the 70's has grown to 75-100 models annually which are used primarily for exhibit purposes.

Scale Reproductions regularly builds custom models for Fortune 500 companies such as Lockheed Martin, Northrop Grumman, and General Dynamics to name a few. The range of clients served extends from heavy industries biggest names to the most exclusive yacht builders and customers including Donald Trump and Jimmy Buffet. One of the company's most challenging projects was a 500 pound scale model of the nuclear-powered aircraft carrier, the USS Ronald Reagan. The 12.5 foot long model was recently installed in the National Museum of Naval Aviation in Pensacola, Florida. While it usually takes the company 90 days to make a reproduction, construction of the aircraft carrier took six months and over 1500 man-hours.

They pride themselves on the details, miniature photos in tiny frames, genuine teak decks, nets full of tiny lobsters. Attention to detail is an integral part of the company's service philosophy and that includes utilizing precise technology to create the models.

When the company started in the 1970's, scissors, an exacto knife and a tube of glue were the tools of the trade. Today, the company uses the most accurate technology in their work: CAD software, laser cutters, a computer-controlled router and robotic prototyping machine (FDM) which builds any component in a 3D format.

Quality control is key to the company's success. No details are left out of consideration, not even the miniature blown out "flip flop" on the deck of Jimmy Buffet's model.